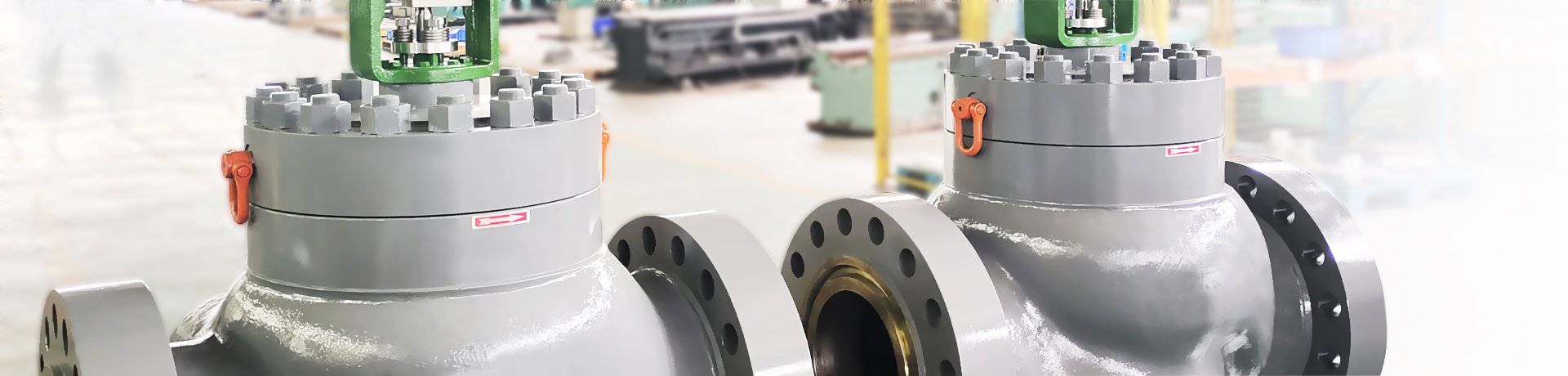

Pilot High Temperature Steam Putting Air Conditioning Node Valve

Product details

The pilot high -temperature steam air conditioning node valve is a special operating conditioning valve for the design of the high -temperature steam empty work conditions.

The basic type of pilot high -temperature steam air conditioning node valve is a direct valve body, a pilot balancing valve core, a low exhibition sound, and a multi -level anti -pressure -lowering sleeve regulating valve, which is used in very harsh working conditions. The fluid is mainly adjusted by the sleeve of the special drilling. The sleeve provides a continuous guide for the valve core. The unbalanced force generated by the flow -level structure rely on the fluid flow clearance when the valve is closed to ensure that the valve core density seals can be cut tightly. The specially designed pilot balancing valve core can open the valve for only a small thrust. The patented all -metal -oriented ring and pure metal dilute seal can ensure that the IEC leakage grade V -level can be met under high temperature conditions of 566 ° C, and there is no actual temperature limit for use. (Patent number: ZL201621067704.1)

The pilot -type high -temperature steam air -conditioning node valve is usually equipped with a FITER pneumatic thin -film multi -spring execution mechanism. The cylinder -type single -double action execution agency, electric or hydraulic execution agency can also be selected as required. The switching time can reach <1S.

Product properties

Technical Parameters

● Nominal diameter: NPS 2'-NPS 24 '(DN50-DN600)

● Nominal pressure: ANSI 150-2500#

● Connection method: flange connection, welding connection

● Upper cover form: standard type, heat dissipation type

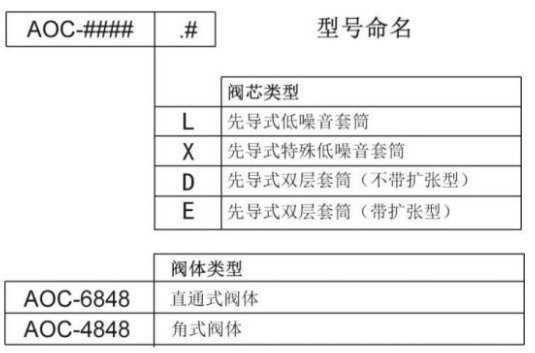

● Valve core shape: pilot valve core (see the figure below)

● Valve flow: Flow to Close Flow Customs Structure

● Flash material: flexible pure graphite filler combination

Online message

If you have any needs, please fill out the form below and we will contact you as soon as possible.