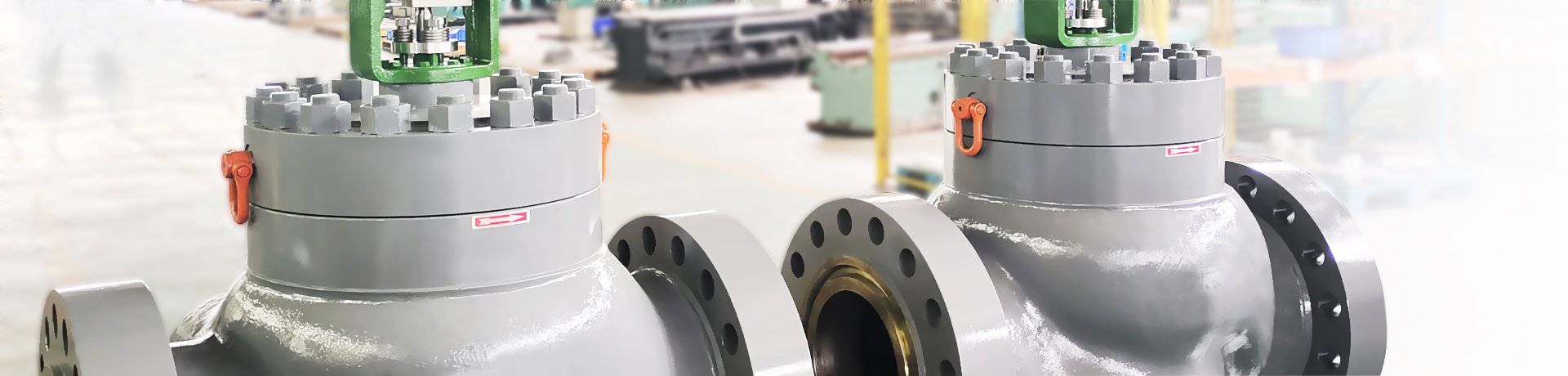

Tripple Offset Metal Seated Butterfly Valves

Product details

The FITER triple offset butterfly valve provides a bi-directional bubble tight shut-off. This geometry ensures that the disc seal contacts the body seat only at the final shut-off position without rubbing or galling ~providing a torque generated resilient seal with sufficient "wedging" to ensure a uniform seal contact.

Product properties

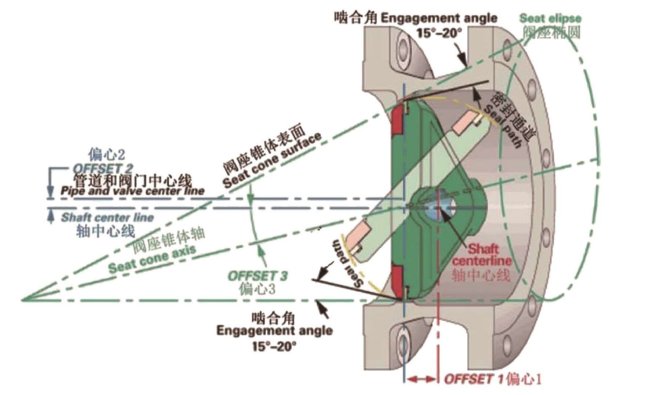

The Triple Offset Geometry

Offset 1 - The shaft is offset behind the seat axis to allow complete sealing contact around the entire seat.

Offset 2 - The shaft centerline is offset from the pipe and valve which provides interference free opening and clos- ing of the valve.

Offset 3 - The seat cone axis is offset from the shaft cen-terline to eliminate friction during closing and opening

and to achieve uniform compressive sealing around the entire seat.

Product Description

Design of tripple-eccentric: It is ap- plicable to the severe service conditions of high temperature and pressure, as well as low leakage During opening or closing, it features non-friction and low torque. The larger the fluid force is, the better the sealing is.

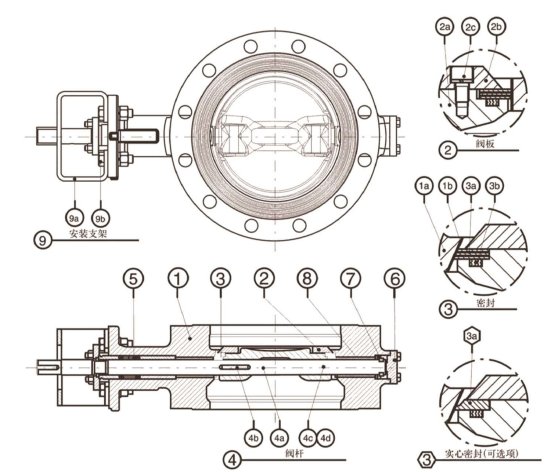

Stepped sealed for anti-blowing out: It can guarantee the security meanwhile the integral stem of high strength material can improve the allowable pressure drops.

The driving method of stem and disk uses offset of round pin: It can avoid the strength of stem decreasing for drilling, thereby it can improve the shearing strength of round pin. as well as reliability and security.

Integral structure of seat ring and body: the sealing face surfacing by high- strength alloy can guarantee the reliability of sealing face and prolong service life, so as to near to non-maintenance.

Various sealing selection: ncluding multi-layer composite sealed multi layer all-metal sealed and integral all- metal sealed. it makes a choice according to the different service conditions. multi-layer composite sealed features flexibility to get better fitting between seat ring and sea ring so as to meet ANSI VI leakage class.

Thrust collar: Stem protecting thrust collar can avoid the dead angle area between stem and body accumulated by particles or coking substance so as to the stem jammed. Flowing in reverse it can prevent stem from rational displacement for fluid force, as so to cause the larger leakage.

Design of Stem sealing: stem sealing of high temperature resistant non-metallic material can prevent the fluid with particles from entering bearing, so as to avoid locked or jammed.

Belleville springs-dynamic loading and Compensation: the packing system uses dynamic loading and compensation of Belleville springs the hole of packing box uses rolling and pressing. the stem is processed by. which can eliminate the packing emission to meet ta-luft standard.

Convenient maintenance: High precision of parts and components on- site regulation and replacement of seal rings.

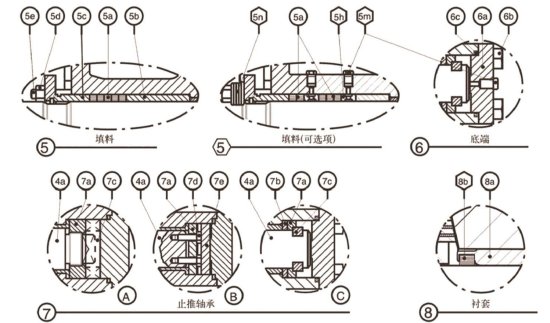

Valve Construction:

Online message

If you have any needs, please fill out the form below and we will contact you as soon as possible.