Spring Loaded Double Parallel Sliding Gate Valves

Product details

Compared with the wedge valve, the spring compensation dual -table valve is smaller than the wedge valve. The inside of the valve board is used in the Inconel butterfly springs instead of the spiral spring. The phenomenon of stuffed phenomenon caused by adhesion and wedge-shaped squeezing pressure under high temperature conditions. The surface of the valve board and the valve seat is hardening (stacked hard alloy, the surface spray Co-CR-NI alloy, spray WC, boron, etc.) With self -cleaning function, the highest surface hardness can reach HRC90 or more; spring compensation dual -table valve can be combined with pneumatic execution agencies, electric execution agencies, electric hydraulic execution agencies or manual execution agencies.

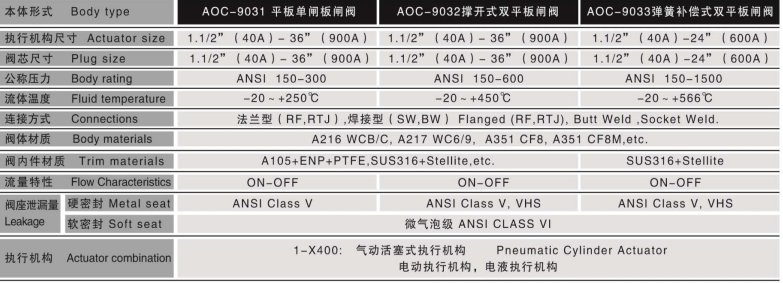

Product properties

Design Features

● The stress seal valve cap uses high -density pure graphite pads

● In order to protect the pressure of the valve cover, the pressure device is introduced

● Use the flat valve of the spring pre -tightening gates

● Relatively wide valve seats and gate

● Limited device circulation application on the branch pole

● There are anti -rotation devices on the valve stem

● The hardness of the two ends of the cover surface is different, there is no large wear,

and the cover has poor hardness (~ 5HRC): the gate -Stl6#, valve seat -stl12#*valve

cover with a sealed-cone type*two-way flow flowing

● Two thrust bearing and aluminum bronze sleeves

● The available structure of the bypass pipeline

弹簧补偿式阀板组件

Graphite ring pressure self -seal structure

● The greater the pressure, the higher the sealing power.

● In the case of high temperature or frequent temperature changes, we recommend using graphite pressure sealing cushion to replace the standard soft iron pads to apply at high temperature and frequency temperature circulation application

Online message

If you have any needs, please fill out the form below and we will contact you as soon as possible.