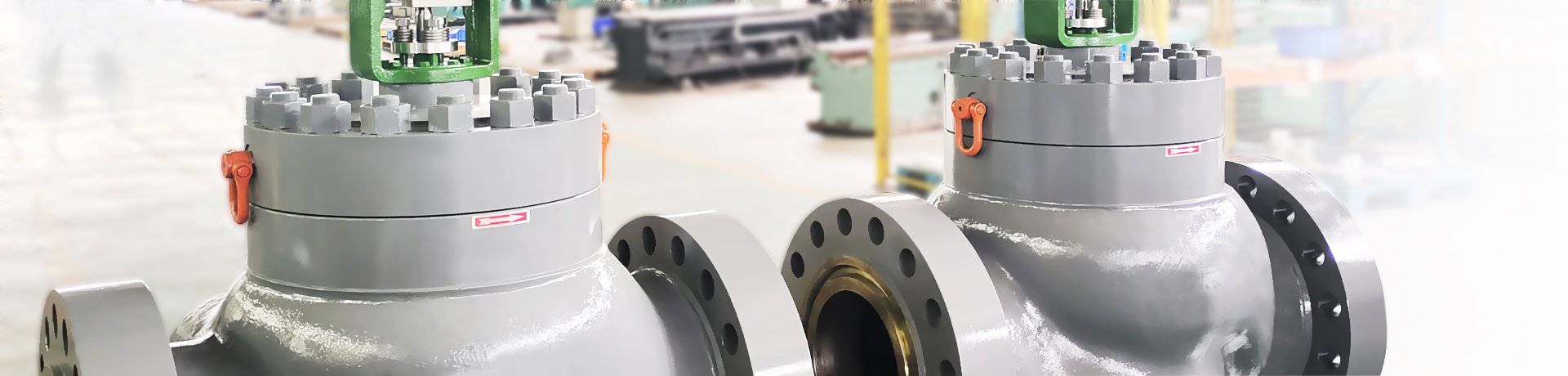

High Temperature Flue Gas Series Four Links to Cut Off Butterfly Valves

Product details

● Sulfur tail gas recycling (smoke emissions reaching standard)

● Catalytic hood export replacement of water seal can

● Skin device molecular screen transformer adsorption benne anhydride smooth

anhydride condensate switch system

● Steel coke furnace exhaust adjustment

● Boiler induction wind delivery system regulate coking reorganization heating

heating furnace replacement

Product properties

● Design standard: API598 API607ASME B16.34

● Standard size: NPS12 "-160" (DN300-DN4000)

● Pressure level: PN2.5-PN20/Asme class 150

● Applicable temperature: -20 ~ 800 ℃

● Leakage level: ANSI B16.104 VI, API598 zero leak

● Valve body material: ASTMA105A351CF8M/special alloy, etc.

● Inner part of the valve: A479-316; S2205; 17-4PH

● Operation method: manual pneumatic electric electric fluid, etc.

● You can expand the product range according to user needs

Design Features

● The maximum caliber of the welded valve can reach DN4000

● Unique four -link structure design, graphic seal design

● External dual bearing design to prevent the media from entering the bearing and causing stuff

● The bottom of the bottom hydrophobic valve prevent the medium erosion valve body

● High -temperature design can reach up to 800 degrees Celsius

● APL607 fire prevention design

● The overall valve stem design, the anti -mid -axis rhodies out of the design

● Anti -static design

● Anti -error operation design

● A variety of sealing structures are optional

Special Treatment

● Surface sandblasting SA 2.5

A) Sand spraying inside and outside of the valve body B) The surface is detailed after sand spraying, and the paint has strong adhesion

c) If O2 ingredients in the medium> 23.5%, external sandblast treatment, no sandblasting is required inside

● Spray paint treatment after surface treatment

A) The surface temperature resistance can reach 450 ° C after the standard spray paint, and the higher temperature can be treated separately B. The two layers of paint and corrosion are 35 microns

● Valve board dense cover pile welding hard alloy

a) The cover of the valve board can be piled up and welded the alloy, Stellited GR.6,

b) Spray hard alloys such as tungsten carbide, and the hardness can reach HRC 60-7

Online message

If you have any needs, please fill out the form below and we will contact you as soon as possible.