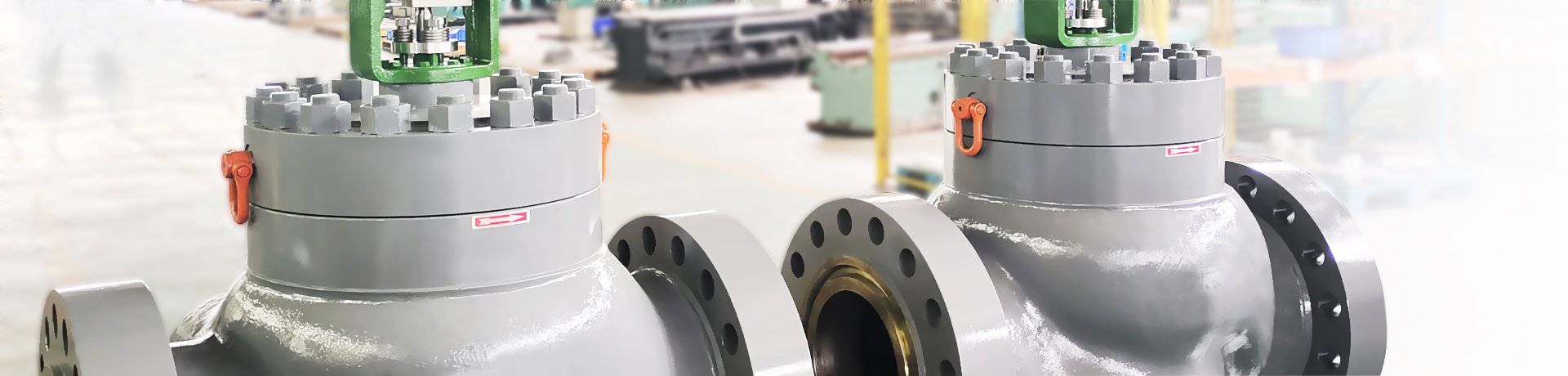

High Temperature and High Pressure Boiler Sewage Discharge Valve

Product details

High -temperature and high -voltage boiler sewage discharge valves are widely used in continuous stream control or intermittent discharge of boiler water. It is a special design specially designed for high -voltage difference, large flow rate, and serious scouring of boiler water discharge. , Candidate and Y -type structure sleeve -oriented multi -stage antihypertensive structures, as well as the design of the Valley pipe export of valve seats, can effectively take the main outlet flow velocity, and the surface hardening treatment greatly increases the service life.

The standard structure of high temperature and high -voltage boiler sewage discharge valve is manual control, and pneumatic and electric control can also be selected according to the requirements. Pneumatic control can be achieved with electromagnetic valves, gas control valves, and fast emission valves. 3s, 4S, etc.

Product properties

Standard Product

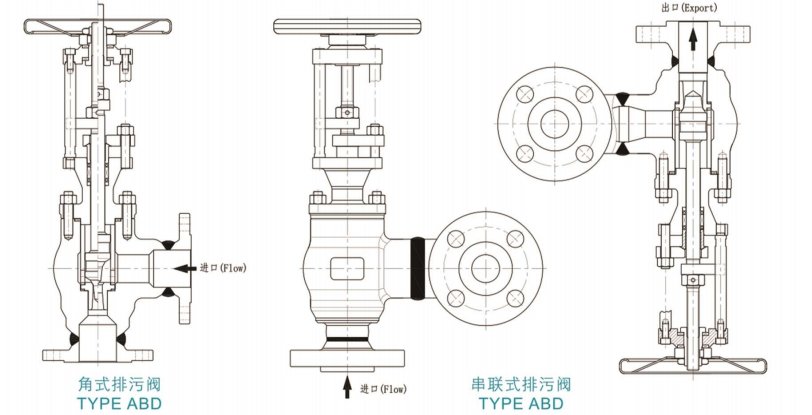

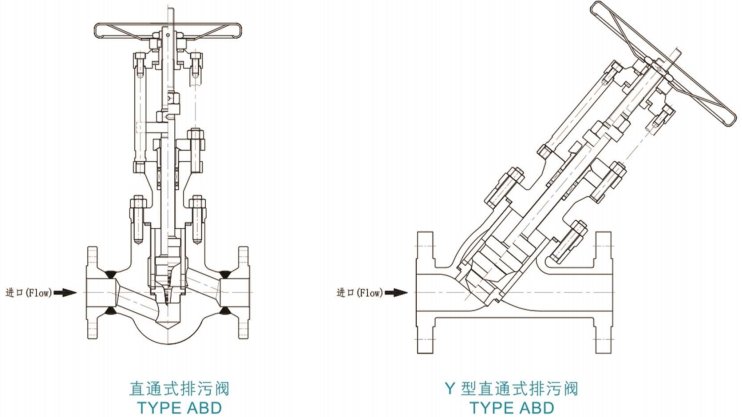

● Type -type direct, corner, series and Y type

● Specification DN20 DN25 DN40 DN50 DN65 DN80

● Nominal pressure ANSI 150-ASI 2500

● The rated itinerary 25 40 50 60mm

● Flow temperature -20 ℃ -566 ℃

● Connecting forms of welding SW, pairing BW, flange Flanged

● Flow characteristics Linear, on-offFF

● Manual operation, aerodynamic operation, electric operation

● Leak level 0 leakage (API 598)

Classification of High -Pressure Boiler Sewage Valve

Continuous sewage valve

It is mainly used for continuous stirring of boiler water. The purpose is to control the content of dissolved chemicals in high -pressure boiler water and prevent dissolved salt after the water saturation of boiler water. In order to recycle (Flash Tank) stored in other low -voltage applications, and continuously discharged boiler water can also be directly applied to the chemical component content in water.

Intermittent sewage valve

The intermittent sewage valve is divided into the bottom sewage valve and blowing and discharge valve. The bottom sewage valve at the bottom is usually directly installed at the bottom of the boiler. It mainly uses the pressure of the boiler's own pressure to regularly discharge the granules, dirt and other sediments at the bottom of the boiler to prevent blockage caused by pipelines. ; Blow sweeping the sewage valve is mainly used for fast blowing and mixing of stacking and stuffing of stacking and stacking pipelines on the boiler pipeline, and the emissions of the boiler condensed water, and so on. The Y -shaped structure is usually used, which has good circulation performance and is not easy to accumulate solid particles.

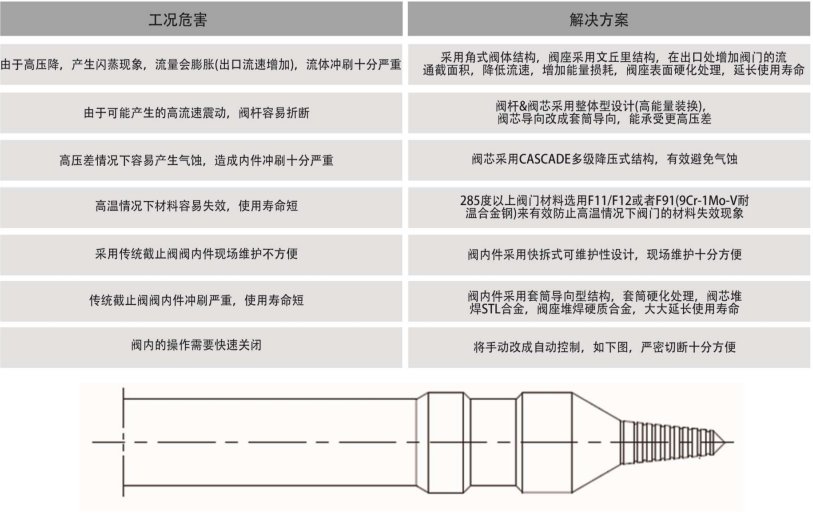

Advantages of High -Pressure Boiler Sewage Valve

The importance of water discharge and discharge of boiler water in petroleum petrochemical and power boilers has been ignored, and incorrect emissions will cause energy waste, heat loss, increase additional chemical treatment costs, etc. It has the same temperature and pressure as the water in the boiler, which can be used to apply it to other boiler's working conditions and so on. The advantages of boiler water emissions are as follows:

● Great reduction of maintenance and maintenance costs

● Automatic control can greatly shrink the cost of labor

● You can get more clean and efficient steam

● Avoid waste of resources and reduce operating costs

● To minimize energy loss, at least 2%of energy loss can be saved each year

High -temperature and high -pressure boiler sewage discharge valve structural diagram

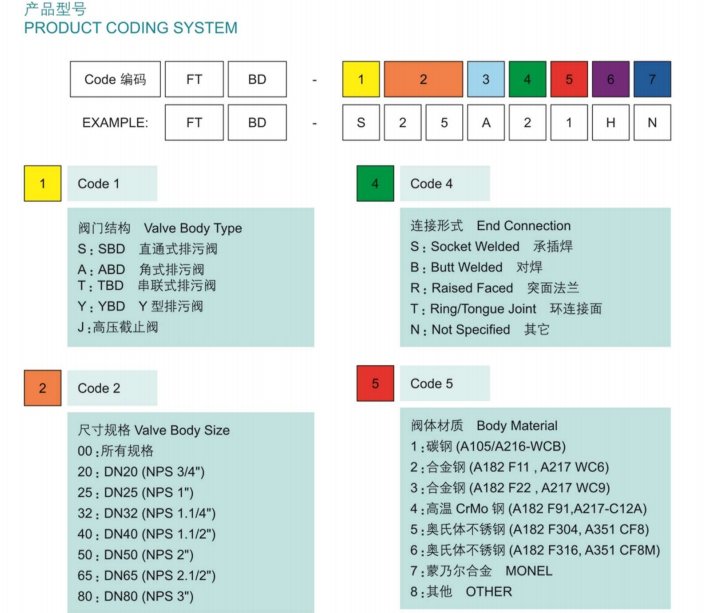

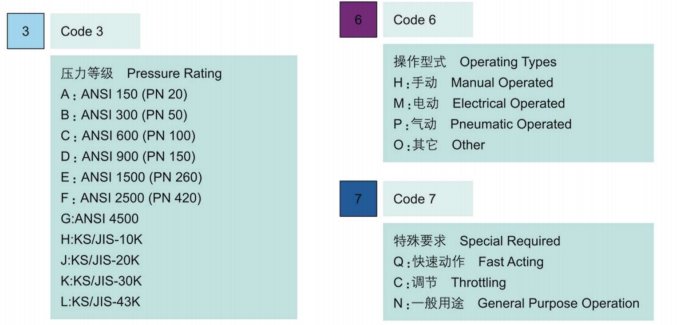

排污阀编码规则

Online message

If you have any needs, please fill out the form below and we will contact you as soon as possible.